F100 Engine

The PW-F100-220/220E is a versatile and durable engine utilized in the F-16 and F-15 aircraft worldwide. This engine is manufactured and supported by the Original Engine Manufacturer (OEM), Pratt & Whitney.

Since 2001, MEPC has provide MRO services on PW-F100-220/220E engine for the RSAF F15 C and D fleet.

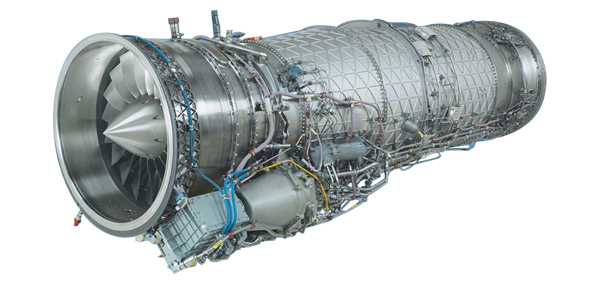

F110 Engine

Today’s F110-GE-129 offers maximum mission capability for the latest generation of F-16C/D and F-15 aircraft.

Sharing 81% parts commonality with the F110-GE-100 – the safest single-engine powerplant in U.S. Air Force history in its class – the -129 offers significant mission advantages throughout the F-15 and F-16 envelopes. For example, more than 30% additional thrust is available at critical low-altitude combat operations.

The F110 powers more than 70% of today’s most advanced USAF F-16C/D aircraft (including 100% of all USAFE and PACAF assets) and offers sustained deployment in every major theater of operation.

F110/F-15 power was first selected by the Republic of Korea (ROKAF) in 2002. The Government of Singapore and the Royal Saudi Air Force have also chosen the F110-GE-129 to power F-15 fleets.

GE has introduced hardware upgrades capable of allowing the -129 to operate for 6,000 TACs between scheduled visits, which represents a 40% reduction in scheduled engine visits.

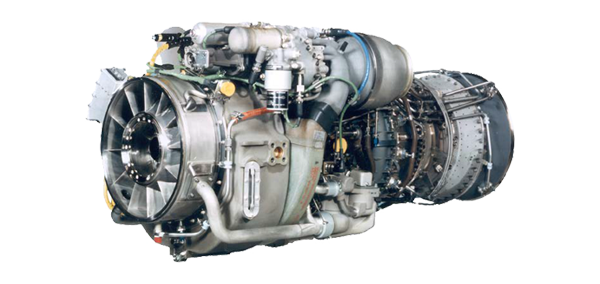

GE T700 701D

GE T700 701D

The T700 military turboshafts have earned a reputation for exceptional performance in combat and under the worst environmental conditions. Designed to be rugged, reliable and easily maintainable, current T700 models apply advanced technology to an experience base of more than 50 million hours of operation.

MEPC has developed local capabilities to perform a complete T700 MRO services.

RB199 Engine

The Turbo-Union RB199 is an aircraft turbofan jet engine designed and built in the early 1970s by Turbo-Union, a joint venture between Rolls-Royce, MTU and GE Avio Aero. The RB199’s sole production application is the Panavia Tornado.

MEPC has been providing MRO services on the High Pressure Compressor (M03) and the Intermediate Pressure Turbine Rotor (M10) modules since 2009.

T56 Engine

The Allison T56 is a single shaft, modular design military turboprop with a 14 stage axial flow compressor driven by a four stage turbine. It was originally developed by the Allison Engine Company entering production in 1954, and is now produced under Rolls-Royce which acquired Allison in 1995. The commercial version is designated 501-D. Over 18,000 engines have been produced since 1954, logging over 200 million flying hours.

MEPC is Authorized Maintenance and Overhaul Facility (AMOF) by Rolls Royce, Provides MRO services on the T56 engines for the RSAF C-130 Hercules aircraft. This service commenced since 2010 with the first modules being shipped for MRO services.

EJ-200-Engine

The EJ200 is being developed and produced in an international cooperation among Rolls-Royce, GE Avio Aero, ITP Aero and MTU Aero Engines. The EJ200 has been designed to fulfil the demanding engine requirements set for the next generation of training and fighter aircraft. Equal priority has been given to performance and life cycle costs. The EJ200 engine has been designed for the Eurofighter.

MEPC currently Provides MRO services on the EJ200 engines for High pressure compressor (M05) & High Pressure Turbine rotor (M12).